Who we are

Pentangle Engineering Services Ltd was formed in 2004 to provide the manufacturing sector with specialist machine services and support.

The story begins in 2004...

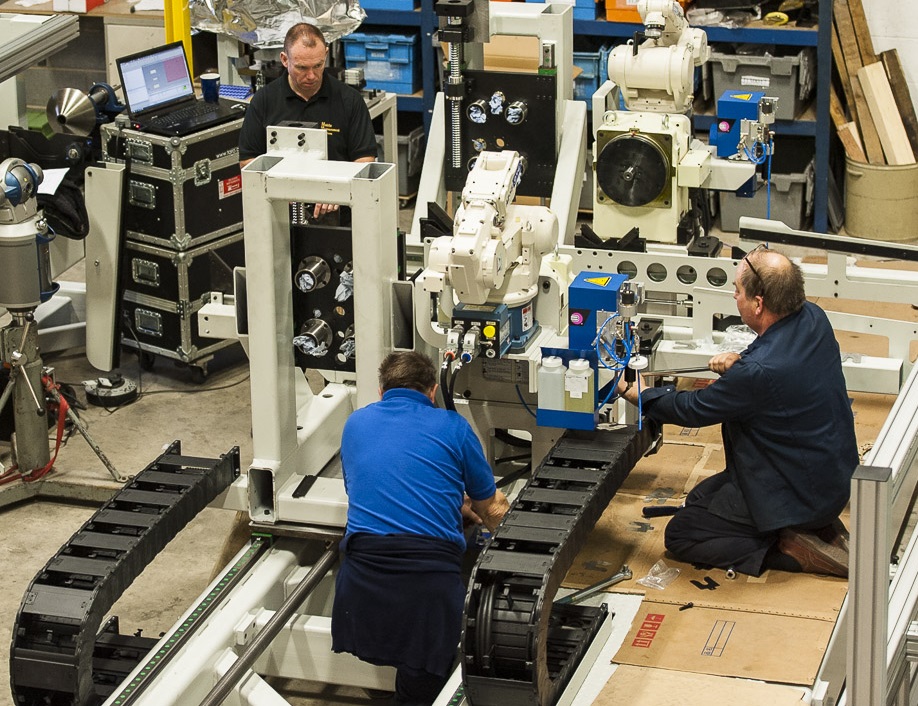

Pentangle specialised in the production of robot systems, special purpose automation machinery and support and branded itself as a robotics and automation solutions provider to enable it to gain exposure in different market sectors.

The experience and expertise possessed by the co-founders enabled Pentangle to offer the complete engineered solution. Many robotic, welding and automation companies at this time could not offer an in house ‘turnkey’ solution. We could.

New premises in 2009...

Pentangle started with a strong mechanical and electrical design background, which enabled the company to offer sound engineered solutions and placed a big emphasis on customer support and service. Where many others failed Pentangle flourished.

We purchased a new 4000 sq. ft. manufacturing and office facility in May 2007 and moved from the old factory to the new premises. Then in early 2009 we gained the accreditation for ISO9001 (2008).

New fabrication department in 2011...

Increased workloads and additional members of the team needed to be catered for and Pentangle expanded into the next door unit, another 4,000 sq. ft. manufacturing and office facility, in 2009.

Further increases in workloads and shortages of skilled personnel, led Pentangle to take on its first apprentice in September 2011.

In November 2011 a new in house fabrication department was set up. This was a great success and soon became Pentangle Fabrications, a trading name of Pentangle Engineering.

Award winning and stronger today...

In 2013, Pentangle Engineering won “The Business of the Year” at the Grantham Business Awards. Since then, Pentangle has become involved with several local charities and is now part of the judging panel for the Awards.

To date Pentangle has grown to 25 team members and occupies units totaling 18,000 sq. ft. Within these units we have equipment including a new laser cutting system, a C.N.C press, a robotic demonstration area and a powder coating plant.

Meet the Pentangle team

Nigel Rivers

Grantham born and bred, engineering is in Nigel’s blood, having started his technical engineering apprenticeship over 40 years ago. Working his way up the ladder with various engineering businesses, Nigel developed an expertise for dedicated and robotic automations machinery, specialising in automotive applications.

In 2004, Nigel established Pentangle Engineering with two colleagues, initially providing maintenance and robotic tooling. Rapid growth of the business followed and in 2019 Nigel became managing director. With a focus on business development, Nigel’s approach to partnership working applies as much to the Pentangle team as it does to Pentangle customers.

Describing his role in three words, Nigel is final decision maker, the overseer and the company counsellor!

Kevin Meakins

Another Granthamian, Kevin has worked with what were some of the world’s leading engineering companies of their time, including Aveling Barford construction equipment.

With a career in engineering spanning nearly 45 years, Kevin has developed an unrivalled technical expertise in robotic welding, robotic automation and the design of specialised machinery and tooling, particularly within the automotive sector.

Moving to Pentangle Engineering in 2005 to work with Nigel Rivers as the company’s technical director, Kevin has been responsible for the company’s technical expertise and today works alongside customers to design and build automation solutions that solve their manufacturing problems.

In addition, he provides a support role to Nigel in terms of the day-to-day running of Pentangle including project costings and sales support.

Tom Tyndall

A Dubliner by birth, Tom began his working life by joining the RAF as a navigational instruments’ mechanic and over a 19-year career developed an expertise in avionics engineering. Avionics (a blend of aviation and electronics) are the electronic systems used on aircraft.

This experience served Tom well for his next roles, developing skills within robotics and lasers and, in 2006, he joined Pentangle Engineering as a laser service engineer. However, Tom’s ability to understand complex electronics saw him move very quickly into electrical design and in 2017 he became electrical systems director.

Tom’s role today involves working with the mechanical design team to understand what tasks a machine needs to perform and then designing the electrical systems, writing the software, and then commissioning the hardware and software to provide the final automated solution.

Dean Ephgrave

The face of Pentangle Fabrications, Dean is responsible for the control of all work through the fabrications department, including liaison with all fabrication customers.

Entering the industry in 2011 through a four-year CNC machining and manufacturing apprenticeship straight from leaving school, Dean developed skills based around CNC lathes, milling machines and machining centres. This included loading, setting, operating and programming automation machinery, with a focus on Mazak and Fanuc machines.

Dean joined Pentangle in 2018 having further developed his skills to include Kuka robotics programming, specialising in robotic welding. Since then, he has progressed from CNC press brake operator to fabrications manager and this hands-on knowledge and experience is invaluable to Pentangle Fabrications and its customer base.

Our quality standards

Pentangle carry many Quality Standard certifications. To view these please click the relevant icon below:

Andy Wadmore